How To Rebuild A Nitro Engine

We will take you through step-by-step instructions showing you how to rebuild your engine.

We show the Nitro Star 15FE in these pictures, however these steps are basic in rebuilding any R/C 2-stroke car, buggy or truck engine. Part numbers required or recommended for HPI brand engines will be noted in the tables on this downloadable PDF file, your engine may require different part numbers if it is not an HPI engine.

First, we start with taking the engine out of your car or truck. By the time your engine requires a rebuild (every one to three gallons of fuel (approx. 5-15 liters), depending on how you care for your engine) you should be somewhat familiar with this step, especially if you built your kit. If you did not build your kit, find the part of your instruction manual that describes the installation of the engine and see what needs to be removed to take off the engine. It is beyond the scope of these instructions to show you how to remove the engine and anything attached to it - see the Instructions Page for your kit for details.

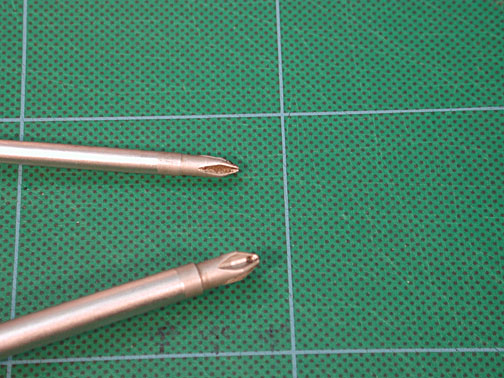

The next step is gathering the required tools - in the picture below you can see the engine (15FE) in the top right, with the tools below: needlenose pliers, #1 and #2 Philips screwdrivers (with hardened tips), 2.5mm Allen wrench. While you have the engine out of the car you may decide to upgrade the flywheel/collet set, replace the wrist pin, wrist pin clip and connecting rod. If you decide to upgrade the flywheel, you will also need the tube of light grease that came with your Nitro kit, or an equivalent grease.

Hardened-tip screwdrivers are highly recommended because they lessen the chance of damaging the screw heads and the screwdriver tips and last much longer than "bargain bin" screwdrivers.

The parts needed for the rebuild are the piston/sleeve set and head shim/gasket set for the engine. Make sure that you have the correct piston/sleeve set and shim set for the engine you own. Please consult your engine's instruction for the correct part numbers.

Once you have all the parts you need for the rebuild, you're ready to begin.

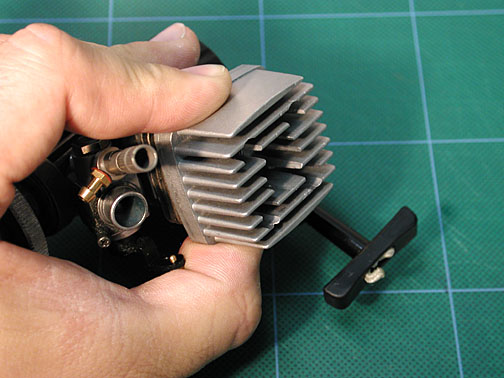

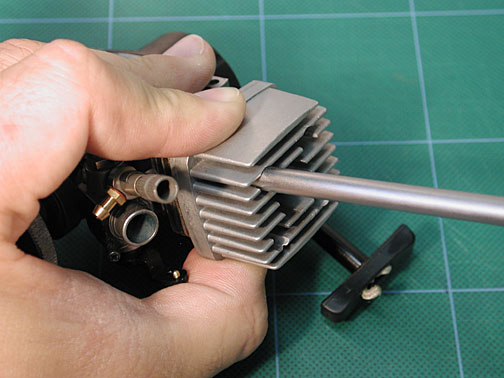

Check the type of screw holding the heatsink head on the engine case. The 15FE uses #2 Philips head screws; the Nitro Star Pro engines use flat head screws, other engines may use hex screws, make sure you have the correct size. It's very important to use the correct size screwdriver - #2 screw require the #2 screwdriver, NOT the #1 screwdriver. You will have a hard time removing the screws and possibly damage the screws if you use the wrong size screwdriver.

Please note that the engine used in this example is an HPI 15FE engine - you may have a different type or brand of engine, but the process is still the same. You will have to check the screws that need to be removed because the 15FE may use a different type of screw in a particular location than what your engine uses.

Remove the screws with the correct screwdriver or Allen wrench. Put the screws aside, either in a plastic or cardboard parts tub or another convenient location. If they roll off the table you'll have to waste time looking for them!

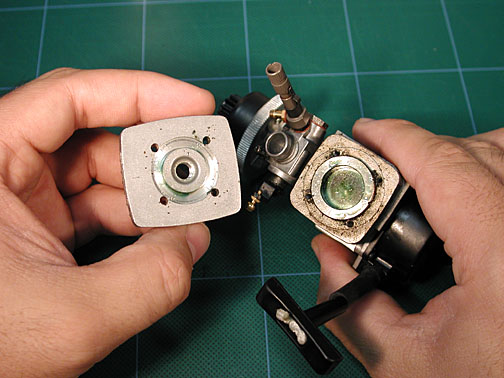

Now that you have the heat sink head off, set it aside also. Remember the way the fins faced so later on you won't have to reposition the head after you install it in your car or truck.

To download the complete guide (PDF), click here.